The Horween Tanning Process

Horween Leather Company: A Look Inside

Understanding the various steps involved in creating a piece of leather.

It all starts with a raw hide. What you see here is our inspection process and the trimming of hides. Once the hide is received, it’s inspected for quality and the hide is processed from here.

The raw hides are then put into cement mixers along with a lime solution, where the hair is burnt off.

The lime solution is referred to as a lime slur and it’s similar to the hair remover Nair.

The skins are loaded at the top of the vessel where that shelf is and turned for 24 hours. At that point, the skin has the hair removed.

From there, the skins are placed into tanning vessels, which are big wooden drums.

Each drum holds about 20,000 pounds of product. The drum pictured here is where Horween does its chrome tanning.

At this point, we're 48 hours into the process you have a product called wet blue.

Wet blue is a hide that is chrome tanned.

Here we have Horween’s vegetable tanning pits, which are about 8 feet deep. The skins are laid in the pits with the vegetable tanning liqueur. The vegetable tanning liqueur is a combination of tree extracts. Horween has been making its own vegetable liqueur at the tannery since 1905.

Vegetable tanning can also be done in drums, but the traditional way to veg tan is with the pits.

After the vegetable tanning process, the hide has more of a neutral color versus the blue color you see from chrome tanning.

After the leather is tanned, the next step is to sort it.

This is arguably one of the most important jobs in the tannery because at that point, this person is deciding what type of leather each individual piece will become. This person reviews every single skin—feeling it, examining the character, the quality of the piece of leather…then decides what type of product it’s going to be.

The wet blue sides are then split to the weight of the customer specifications.

After the leather has been sorted, it’s put back into a coloring drum (also called a re-tan drum).

Up to this point, all of the hides are homogenous. They don’t have a real character because they all have the same base recipe. This is the stage where that starts to change—where the individual formulas are executed. The re-tan drum is where the character, color, and performance of the leather is added through various dyes and oils being added to the re-tannage step.

This is the coloring or re-tan drum in action. It runs in 6-to-12-hour cycles.

Here we have the workers unloading the drum.

You can see a black leather on the right and the Shell Cordovan on the left.

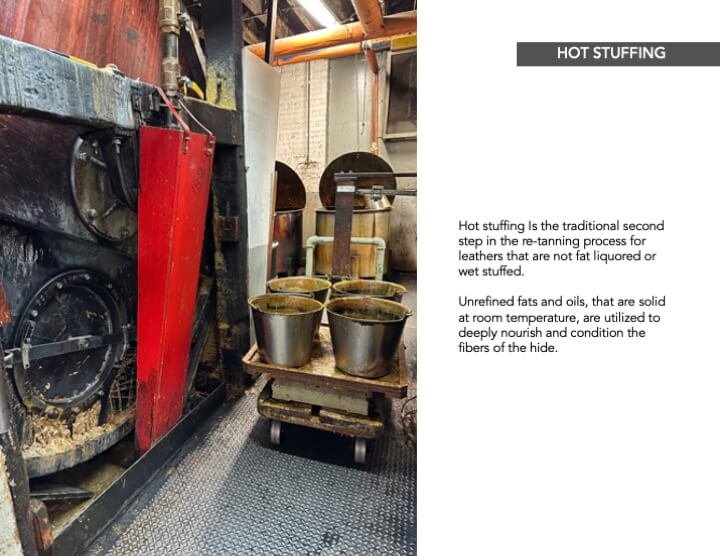

These are the oils used in Hot Stuffing. Hot Stuffing is where the leather is nourished with natural oils and waxes so it doesn't break down over time.

This is a very important step since tanning removes that natural oils of the hide. If you didn’t reintroduce oils and waxes into the hide, you'd have a shoe or end-product that will probably disintegrate in eight to 12 months.

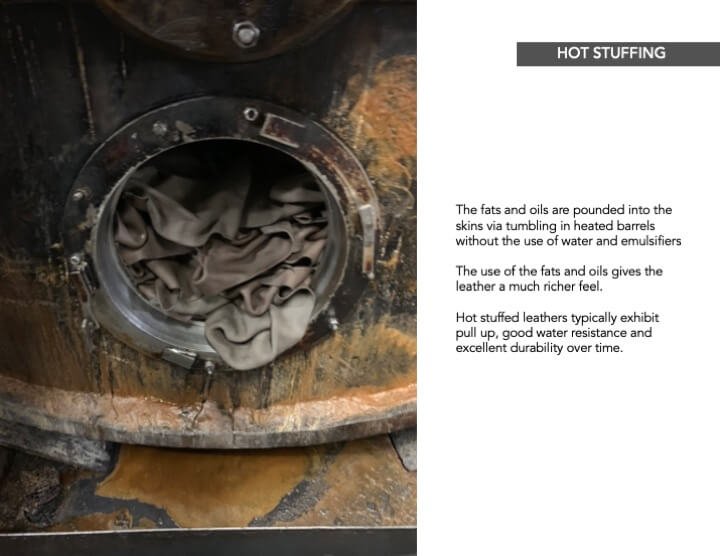

Hot stuffing Is the traditional second step in the re-tanning process for leathers that are not fat liquored or wet stuffed.

Unrefined fats and oils, that are solid at room temperature, are utilized to deeply nourish and condition the fibers of the hide.

The fats and oils are pounded into the skins via tumbling in heated barrels without the use of water and emulsifiers

The use of the fats and oils gives the leather a much richer feel.

Hot stuffed leathers typically exhibit pull up, good water resistance and excellent durability over time.

Air Drying: Air drying is a natural way to let the leather relax back into itself. The leather is put on hooks anywhere from 2 days to 10 days. Air drying lets the fibers gently come back together to create a really tight, consistent, uniform product. Air drying is an old school process, but creates a high quality yield because it lets the skin relax back into itself as opposed to other methods which can stretch the skin and fibers.

This is Chromexcel leather that’s come off the hooks from being air dried.

Pasting: Pasting uses a paste mixture to put the leather on a glass frame and move it through a 5-stage heater. The heater introduces heat to the leather and 4-to-6 hours after it comes out of the other pasting unit it’s dry.

This photo shows workers putting a wet skin onto a glass frame and slicking it so it’s flat. Behind the frame unit where it's going to go to the dryer.

Dry time: about 8 hours. It’s used for Latigo and Football

Toggling: Toggling is an older method of dying where you take clips and stretch the leather on the frame and let it air dry.

The end appearance of toggled leather is a raised, pronounced grain.

On frames for 7-10 days and air dried.

Vacuum Dry: Vacuum drying is the newest and most modern way to dry leather. Vacuum drying sucks the moisture from the leather at low heat, which gives the leather a smooth surface.

Best for waterproof leathers and veg leathers (Essex, Dublin, Derby)

The leather is split it to weight.

The picture shows them gauging to the weight

This photo shows the natural crust getting fed into a machine where it puts a little bit of dye on it, then it’s hand swabbed or hand-finished.

Each piece is hand swabbed 3-to-5 times to build that color.

The goal is not to cover up the grain, but rather really show off that the natural beauty of that leather.

After each coat of hand swabbing, the stains are air-dried for about 30 minutes through a drying tunnel like you see here. The leather will go through this process 3-to-5 times, depending on how many stain coats.

After it’s finished, it’ll get a clear coat sprayed on

The second type of finishing done at Horween is spraying. This is where finishes are sprayed on top of the leather in a spray machine like the one you see here.

There is a bank of electronic eyes that measure the shape of the skin and spray it on

Football, Basketball, & Latigo all go through this machine at one point

Here we have the leather being fed into the spray machine. You can see the spray guns applying the stain to the leather.

Natural CXL getting the clear coat of finish

The picture to the left is the dedicated machine that we only use for embossing Horween football leather and basketball leather.

Right Top: football leather before and after embossing

Right Bottom: Wilson “W” embossed into the football leather

Chromexcel gets slightly buffed with a very fine sandpaper. The red piece on the right picture is sandpaper.

Nubuck gets astronger buffing – raising the grain to get a track

At the end of the process, we sort the leather and put a measurement on the backside of every skin.

You see the tannery name.

The second line shows the square feet: 18.8 square feet

The third line shows the date

This information allows us to track production runs back to a specific order.