Cordovan Q&A

Please click here to email our leather distributors for Cordovan pricing and availability

What Is Shell Cordovan?

Genuine Shell Cordovan is the art of tanning at its finest. Shell Cordovan is a very specific type of leather that comes from the shell membrane of a horse butt. The tanning process takes at least six months.

To reach and expose the shell, the leather is shaved on the flesh side (underside). The irregular oval-shaped shells are tanned, slowly steeped in gentle vegetable liquors, stuffed, shaved, and then polished. The shells are genuine hot stuffed and then slicked onto glass frames to dry. Each shell is hand-curried and shaved by highly skilled artisans to expose the shell. Dyes are hand-rubbed on for a deep aniline finish. Finally, the shells are hand-glazed to achieve the rich, glossy look and feel prized by fine craftsmen.

Horween Shell Cordovan Grading

There are 8 classifications or grades of Horween Shell Cordovan.

Each grade corresponds to a range of square feet in which the shell can fall. In addition to the overall size of the shell, imperfections and defects are taken into account and subtracted from the base square footage.

Horween Shell Cordovan is graded based on two factors...

1. The overall size of the shell

2. The cuttable area of the shell

This means is the imperfections and blemishes in the shell are taken into account when it's graded.

FOR EXAMPLE:

This shell is 2.3 square feet, which would put it in the Large category without human inspection.

However, upon final inspection, markings / blemishes / imperfections were taken into account that were subtracted from the usable area of the shell.

The final grading of the shell is Medium.

Shells are not sorted based on how they look on the unfinished side.

What to expect from Horween Shell Cordovan when ordering

The weight (thickness) of Horween Shell Cordovan is will be around 4 oz (1.6mm) in the center.

The natural thickness of the shell has a large degree of variation where the center of the shell will be around 4 oz (1.6-1.8 mm) and the outer edges of the shell will fall off to approximately 3-3.5 oz (1.2-1.4 mm).

The reason for the variation is that we are truly shaving to the actual shell and the finished leather will show a natural weight variation within the shell and from shell-to-shell.

Splitting can be difficult and should be done with care, however we do not offer splitting services.

There can be color variation between shells of the same color.

Cordovan is a leather that is a full vegetable tanned product and is hand finished. The result is that there will be variation in color from each shell and likely variation within a shell.

Black will be easier with regard to the color variation than the other colors. As a general statement, the lighter the color of the finished Shell Cordovan, the more color variation will be seen.

Horween Shell Cordovan will vary in shape

Shell membrane shapes are irregular. No two shells can be identical as they are a natural membrane and differ from skin-to-skin.

Other tanneries have more regular shapes than Horween Shell Cordovan based on the fact that they are just cutting ovals from the finished leather. They are not truly exposing the shell membrane, which allows for a more uniform shape in the finished leather.

Shell Cordovan has imperfections. Please do not expect a flawless piece.

Imperfections are an inherent part of purchasing leather, and Shell Cordovan is no different. Defects can happen for a variety of reasons, but rest assured you are not paying for those areas. As mentioned above, Horween subtracts the imperfections/defects on the shell from its size category to place it in a final grade.

These marks or holes are not considered items to which a shell would be rejected. The key is to be strategic with your cutting and to work around these imperfections.

Below is an overview of some of the characteristics you can expect when purchasing Shell Cordovan.

HOLES – In some cases, defects are difficult to see and it open up in the lasting process of the shoe manufacturing. Holes occur when Horween notes a defect within the shell that was either inherent to the skin or due to manufacturing and is cut out of the shell.

Shoe manufacturers that use shell asked many years ago that Horween remove issues we see at the final QC sort. Horween is cutting out the defect in order to more easily allow the manufacturer to see the defects and place their patterns accordingly.

Remember, you’re not paying for these areas. Horween Shell Cordovan is graded on two factors. Both the overall size of the shell and the cuttable area. This means they take into consideration the imperfections and defects that inevitably occur in the shell membrane.

WHITE DOTS - The white dots are the natural hair follicles that can be seen within the Cordovan. The reason these can be visible is due to the process where Horween shave the shells from the underside of the skin (the flesh side) to properly expose the shell. There are times that shell shaving will expose the natural hair root of the hide. Horween tries to minimize this though it is a natural character of this unique product. Hair follicles are never considered a defect.

TWO TONED/LINE DOWN MIDDLE - This is an inevitable part of the manufacturing process of the shell membrane. The lines come from the shaving process of the shell cordovan. The shell membrane is shaved by a skilled technician who is using a foot pedal to adjust the pressure of the shaving mechanism. It requires multiple passes to achieve an even level shell.

BOTTOM AREA - The bottom of the shell is an area where the shell membrane ends and the rough surface within the piece of leather is actually an area where the leather has the natural fiber structure rather than the smooth shell.

DULL SHELL – When the oils and waxes move to the surface of the shell, it can appear dull. You should be able to use a soft cloth and rub them back in. This along with the polishing of the finished products should bring it back to a beautiful luster.

SCRATCHES / SCARS – Scars are an inherent part of leather. Cordovan is no different. Scratches happen for a variety of reasons, but are often able to be buffed out or filled in with the Saphir polishing products.

Remember, you’re not paying for these areas. Horween Shell Cordovan is graded on two factors. Both the overall size of the shell and the cuttable area. This means they take into consideration the imperfections and defects that inevitably occur in the shell membrane.

Marbled Shell Cordovan pieces have unique markings—lines, scratches, white marks.

White Marks

If you see a small white mark, this due to the leather being bent and the waxes are creating a white break. This should come out when working the leather with a Cordovan care product (we recommend Saphir).

Small Scratches

There can sometimes be small scratches that are seen due to the process of removing the color ahead of refinishing the leather. The tannery removes the color by the shaving process, and unfortunately this procedure leaves lines in the marbled product. This is an inherent part of the finished leather.

Lines

The lines are just the color difference when we are removing the color from the first round of finishing.

GUIDELINES ON DIMENSIONS

Grade is the square footage of the cuttable area, but we understand that sometimes you need to understand the dimensions of the shells to make sure they fit your pattern. Below are the various grades next to a red ruler. The ruler is 12 inches long (30 cm).

As mentioned, Shell Cordovan varies in its shape and size. No two shells are the same. This is meant as a general guideline only.

Chips: 0.8-0.9 square feet of cuttable area

XS: 1.2-1.4 square feet of cuttable area

S: 1.5-1.6 square feet of cuttable area

M: 1.7-1.9 square feet of cuttable area

L: 2.0-2.4 square feet of cuttable area

XL: 2.5-2.9 square feet of cuttable area

XXL: 3.0 + square feet of cuttable area

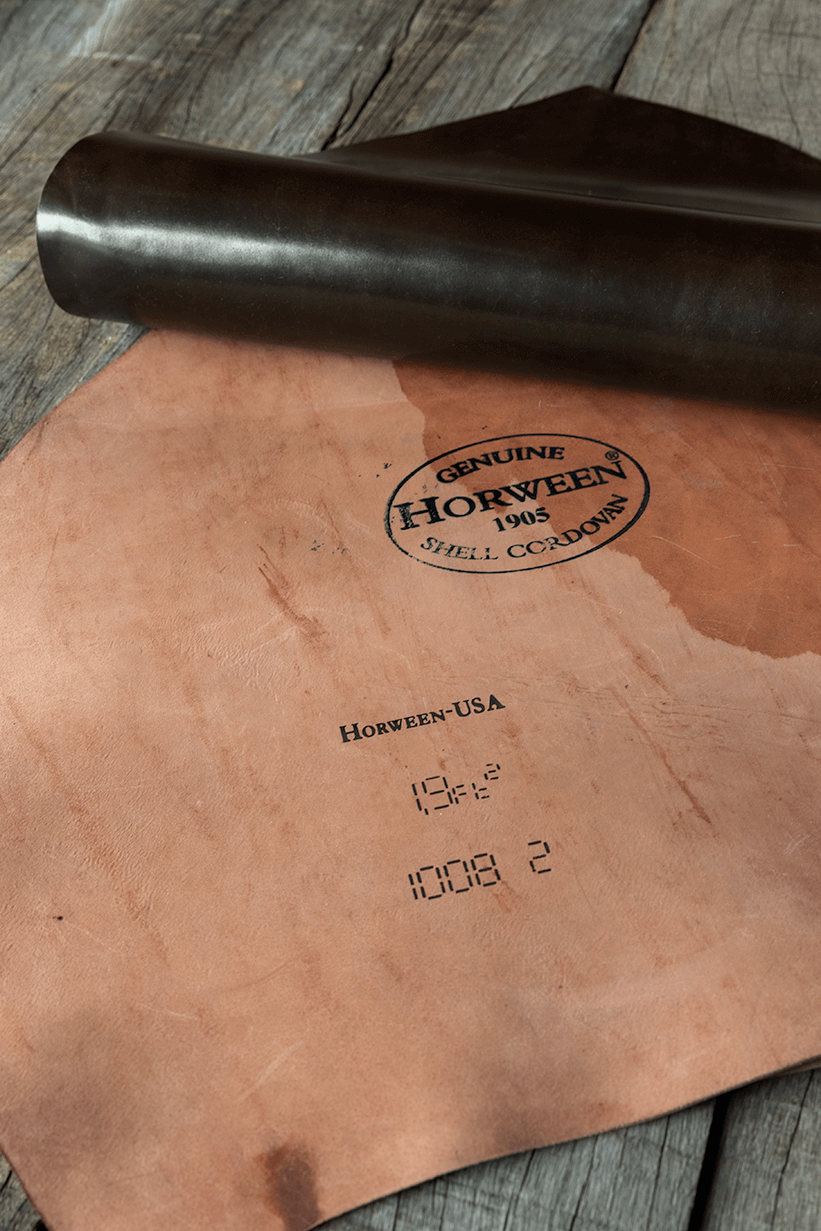

Horween Shell Cordovan Stamps

All pieces of Shell Cordovan automatically get one oval stamp (except for Natural & Bourbon)

There will be one stamp on the back of most colors.

Natural and Bourbon do not always get a stamp. The reason is the ink from the stamp can transfer to the front side of the Cordovan leaving a stain. If you’d like a stamp on your Natural or Bourbon shells, you must request it, and accept the possibility of ink transfer is at your own risk. Of course we will do everything we can to minimize the risk of this happening.

Can I get more than one stamp on my Shell Cordovan?

No, there is a strict one stamp per shell policy.

Horween Shell Cordovan Colors

Natural Shell Cordovan

Natural is the most aniline color made as it does not incorporate any dyes in the procedure and is finished using clear coats.

When will you have Whiskey Shell Cordovan again?

At this time, Horween does not have a plan to provide whiskey again. The dyes that were used to make Whiskey are now obsolete for environmental reasons and the replacement dyes do not allow us to make the color.

The closest color that Horween makes is Bourbon. Whiskey was a bit more yellow than Bourbon.

Is there gray Shell Cordovan?

No, we do not offer a gray shade in Shell Cordovan. The main reason is that Horween only use aniline dyes (stains) to hand finish the leather. Gray colors need pigments to create the final color and Horween does not use any pigments in the finishing of Shell Cordovan.

Other asked about Shell Cordovan colors

Brandy, Color 6, Calvados, Gunmetal, Ivywood, Saddle: These are colors that have been made in the past by Horween, but we won't be seeing anytime soon.

Walnut was been done in the past, and the closest thing now is Dark Cognac.

Ravello, Cigar: Alden exclusive colors

Chili is the same color as Garnet.

Shell Cordovan Care Tips

How to Take Care of Shell Cordovan

Brands we suggest to use on your Shell Cordovan are Saphir, Kiwi, Kellys, and Venetian Cream.

Do not use….

The above are the only liquid creams we suggest as the others have too much solvent and actually hurts the leather over time. Using the wrong product on your Cordovan can damage the integrity of the leather over time.

Tips for Taking Care of Cordovan Shoes

It is important to care for the leather after the shoes are worn. There are no specific steps for care as most companies and customers have found a process that works best for their shoe and the final product. Most will agree that there should be some minimal care through some easy steps and the below are most common:

For general cleaning and polishing:

Clean shoes with damp cloth

Brush vigorously with a horsehair brush

Buff with smooth cloth

Use wax or polish after 10-15 wearings. Applying too much wax will build up the surface and create a cloudy looking product.

The process is really best summarized by one of the style forums:

"The point of all this being that for Shell Cordovan you want to bring out the natural luster from within, not put a shine on top using polishes. The more buildup there is, the worse Shell will look. Less is more."

The other key is that using a shoe tree when the shoes are not in use will help keep the shape.

How do I Waterproof My Cordovan Shoes?

Shell cordovan is exceptionally durable. The pores are so dense on the hindquarters of a horse that they are not visible to the naked eye. The hide is naturally resistant to water (though not impervious).

Each pair of cordovan shoes is somewhat unique. This is due to the secondary finishing of each shell done by the shoe manufacturers (it varies), and the cumulative effect of all the conditioning and polishing the consumer has done to the shoes since they left the factory.

The key with Cordovan is the after care. If the shoes get wet, it is important to wipe the shoes down with a product like the Saphir Cordovan Cream or Saphir Renovator. This should be applied to the shoes, and then polished. It should remove some of the water staining the leather picks up.

Since Cordovan is a straight vegetable tanned leather, the leather does pick up moisture and can swell when wet. The key is to dry the leather out properly when wet.

Other Cordovan Leather Questions

Is Cordovan Leather Available by the Side?

No. Cordovan is a unique product produced from the hindquarter of a horsehide so by definition not available in a side.

Is Cordovan Moldable?

Yes. Since Cordovan is a straight vegetable tanned leather, it will mold well. The key for moldabilty is based on the tannage.

Chrome: Chrome provide great heat resistance and strength

Vegetable: Provides great mold-ability and aging with patina

Tips for Working with Cordovan Leather

The Cordovan can be a tricky leather to work with the first time.

This is a leather that is a full vegetable tanned product and is hand finished. The result is that there will be variation in color from each shell and likely variation within a shell.

The color on the Cordovan is directional and the parts need to be cut in the same direction to have a good color match in the final product (very important if you use two shells for the product).

Cordovan leather does not work well with heat (due to the vegetable tannage) and also does not handle steam well.

It is ok to wet the leather to work it during the manufacturing of the boot and excessive heat and steam will dry out the leather and create a raspy feel over the toe.

Does the color bleed when wet?

The darker the color the more the leather will bleed. All Cordovan (except Natural) will have color transfer. The reason for this is that the stains are applied by hand and there are no tops to seal the color when the leather is finished.

Are Workshoe Butts considered Shell Cordovan?

No. It is a different leather altogether.

Workshoe Butts are the whole butt of the horse with the shell still within the leather. The leather has not been shaved so the shell membrane is not exposed.

Workshoe Butts are combination tanned. They are pit tanned in the Cordovan vats for the first 30 days, then removed and re-tanned with a chrome tannage. Workshoe Butts are hot stuffed with a rich blend of oils and waxes and hand-finished with stains to achieve the final look.

Workshoe Butts are much firmer than Shell Cordovan.

How to Order Horween Shell Cordovan

How do I purchase Shell Cordovan?

Please email info@thetanneryrow.com

Shell Cordovan is not available to purchase online.

What is the lead time on Shell Cordovan?

Lead time can vary due to the demand, but current lead time is 2-4 weeks no matter the color.

Is there a minimum order quantity to purchase?

No. For all Tannery Row leather, there is just a 1 piece minimum quantity.

Are there discounts with volume orders?

No. Shell Cordovan is the same price no matter how many pieces you order.